Zurich: Supply chain issues lose UK tech firms £207,000 a year

Insurance provider counts cost of supply chain problems on mid-sized tech firms.

Sign up today and you will receive a free copy of our Future Focus 2025 report - the leading guidance on AI, cybersecurity and other IT challenges as per 700+ senior executives

You are now subscribed

Your newsletter sign-up was successful

Supply chain disruptions are costing mid-sized UK tech firms an average of 207,000 a year, according to findings from the Zurich Financial Services Group.

The company's Weakest Link: UK Plc's Supply Chain report looked at 500 businesses in five sectors: manufacturing, technology, food and beverage, sport leisure and entertainment and wholesale businesses.

Eighty-eight per cent of organisations across all five sectors have reportedly experienced "significant disruptions" to their supply chain.

Dave Carey, head of corporate insurance at Zurich, said: "The research shows that mid-corporate businesses, across a variety of sectors, are still prone to severe supply chain disruptions that can dramatically affect their bottom line.

"A well managed and maintained supply chain is essential to the efficient workings of a company. However, the failure to prepare for the worse scenarios can have devastating consequences that resonate across a business, regardless of size," he added.

Eighty-eight per cent of technology companies reported disruptions, with the top three most common causes being IT outages (52 per cent), adverse weather (40 per cent), and product quality incidents (39 percent).

The report showed that technology companies experienced an average of five weeks of disruption because of supply chain challengers, with half experiencing loss of orders and sales.

Sign up today and you will receive a free copy of our Future Focus 2025 report - the leading guidance on AI, cybersecurity and other IT challenges as per 700+ senior executives

Fourty-eight percent reported increased operating costs and 41 per cent suffered reputational damage.

Despite the contribution supply chain management makes to a company's bottom line, 60 per cent of technology firms said they had not reviewed their supply chain arrangements in the past six months.

Nick Wildgoose, global head of supply chain at Zurich, said: "The lack of preparation and business continuity planning amongst businesses, particularly those who are highly dependent on suppliers, is alarming.

"This is despite high profile events such as the volcanic ash cloud, the Japanese tsunami or the Thai floods, for example.

"Businesses need to map out their key suppliers and plan for the worst case scenario, or suffer significant disruptions and associated financial impacts," he concluded.

-

AWS CEO Matt Garman isn’t convinced AI spells the end of the software industry

AWS CEO Matt Garman isn’t convinced AI spells the end of the software industryNews Software stocks have taken a beating in recent weeks, but AWS CEO Matt Garman has joined Nvidia's Jensen Huang and Databricks CEO Ali Ghodsi in pouring cold water on the AI-fueled hysteria.

-

Deepfake business risks are growing

Deepfake business risks are growingIn-depth As the risk of being targeted by deepfakes increases, what should businesses be looking out for?

-

What the US-China chip war means for the tech industry

What the US-China chip war means for the tech industryIn-depth With China and the West at loggerheads over semiconductors, how will this conflict reshape the tech supply chain?

-

The Forrester Wave™: Third party risk management platforms

The Forrester Wave™: Third party risk management platformsWhitepaper The 12 providers that matter the most and how they stack up

-

Apple to shift MacBook production to Vietnam in further step away from China

Apple to shift MacBook production to Vietnam in further step away from ChinaNews The plan has been reportedly been worked on for two years, with the tech giant already having a test production site in the country

-

Food and beverage traceability

Food and beverage traceabilityWhitepaper Understanding food and beverage manufacturing compliance and traceability

-

Ensuring compliance with the National Bioengineered Food Disclosure Standard (NBFDS)

Ensuring compliance with the National Bioengineered Food Disclosure Standard (NBFDS)Whitepaper How food manufacturers can enhance traceability with technology to be compliant

-

The future of manufacturing

The future of manufacturingWhitepaper Digitally transform your business and get ready for Industry 4.0

-

Microsoft targets optimised supply chain investments with new platform launch

Microsoft targets optimised supply chain investments with new platform launchNews Microsoft's new Supply Chain Platform fully harnesses Microsoft cloud to help businesses improve supply chain agility and resilience

-

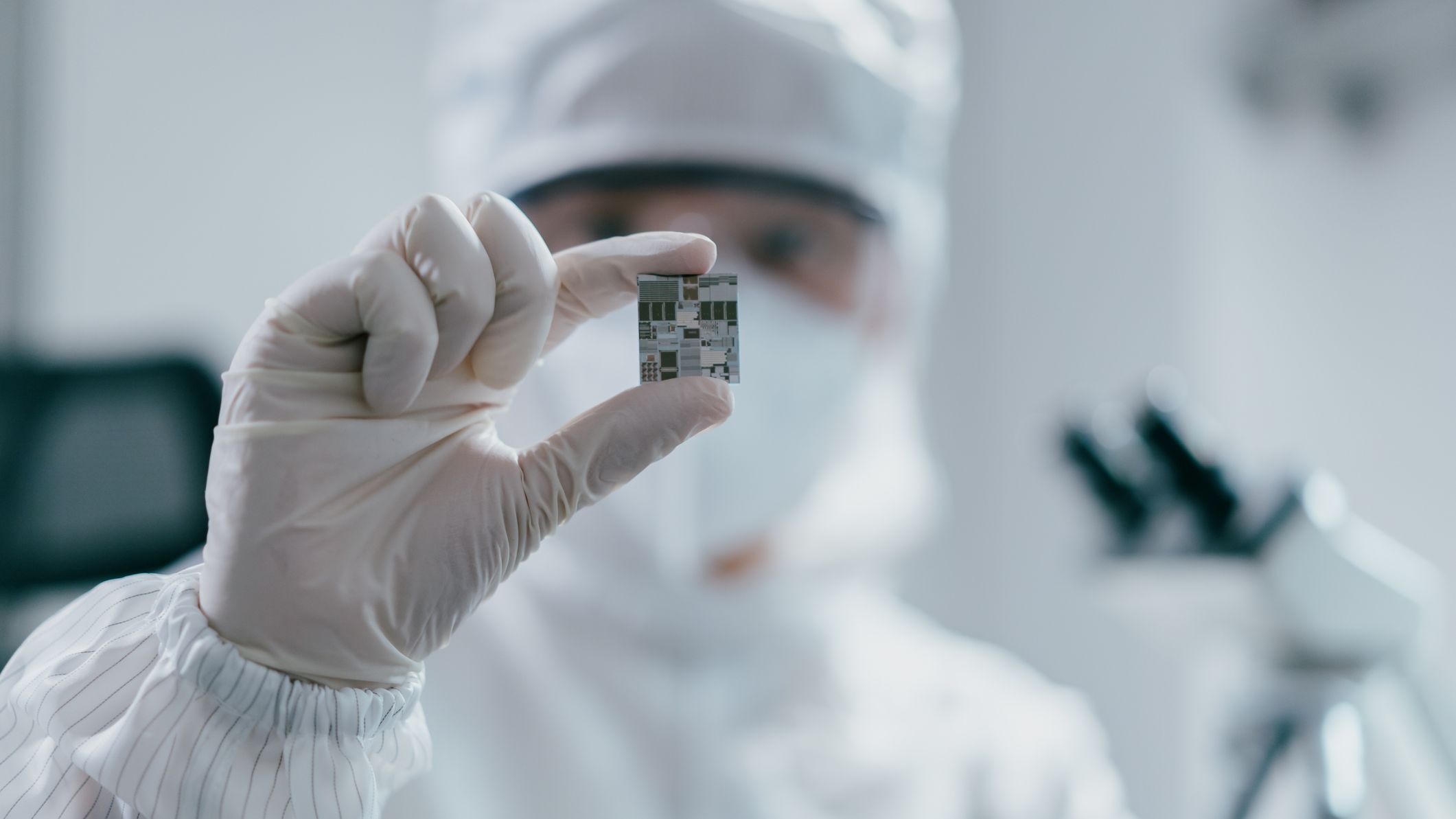

Micron to invest historic $100 billion in NY semiconductor site

Micron to invest historic $100 billion in NY semiconductor siteNews Construction on the site will commence in 2024, with output expected in the late 2020s