MSG giant Ajinomoto's chipmaking foray helps break financial records

In addition to umami seasoning, the company produces a microfilm insulation used by the semiconductor industry which was repurposed from its amino acid technology

The Japanese food giant Ajinomoto has recorded a record-breaking share price after receiving a boost from its technology used to make materials for the semiconductor industry.

The company, famous for its MSG seasoning, saw its share price reach a high of ¥4,357 ($31.46) on 29 November. This beats the company’s former record of ¥4,350 which was recorded back in March 1987, as reported by Nikkei Asia.

The company first expanded into the semiconductor industry in the 1990s, when it repurposed its amino acid technology to develop Ajinomoto Build-up Film (ABF), a microfilm insulation for electronic devices.

This was first adopted by a major semiconductor manufacturer in 1999, but its popularity has surged in recent years due to the chip crisis, especially since ABF has been in scarce supply since the pandemic began.

The company’s non-food segments are predicted to provide over 40% of its overall profit this financial year. Its net profit is on track for a 10% increase to ¥83 billion too, with the semiconductor material production area of the business helping to inflate its earnings the most.

Spurred on by this, the company revealed that it will accelerate the expansion of its ABF technology and may potentially invest more than the planned ¥17 billion ($122 million) to keep up with demand, said Taro Fujie, CEO at Ajinomoto, according to Bloomberg.

Ajinomoto forecasted that its ABF product shipments will grow 18% each year to March 2026, and the growth is predicted to stay in double digits until 2030, said Fujie.

Sign up today and you will receive a free copy of our Future Focus 2025 report - the leading guidance on AI, cybersecurity and other IT challenges as per 700+ senior executives

RELATED RESOURCE

Around 70% of the multinational food company’s ABF goes into data centre servers, and it’s expected that the expansion of 5G will also ramp up demand. It also provides electrical insulation for high-performance CPUs.

The company said that sales in the ABF unit grew 30%, reaching ¥37.2 billion, during the six months ending with September. Ajinomoto’s frozen food business, on the other hand, makes up around 20% of its revenues and reported a loss of ¥300 million in the same time period.

ABF can be found in most of the world’s personal computers, Ajinomoto said. The material is used by most modern chipmakers when designing the smaller components inside CPUs and GPUs.

Ajinomoto said that the need for CPU substrates grew in the 1990s for three reasons. This is because there was a rise in the integrations of CPUs in personal computers, PCs transitioned from MS-DOS to Windows operating systems, and there was an increase in terminals from around 40 to over a thousand today.

"Advances in circuit integration have made possible CPUs composed of nanometre-scale electronic circuits," the company said. "These circuits must be connected to the millimetre-scale electronic components in electronic equipment and systems. This can be accomplished by employing a CPU 'bed' composed of multiple layers of microcircuits, known as a 'build-up substrate'."

It said that the ABF helps to create the micrometre-scale circuits since its surface works well with laser processing and direct copper plating. It's now considered to be an essential material for creating circuitry which guides electrons from nanoscale CPU terminals to the millimetre-scale terminals on printed substrates.

Zach Marzouk is a former ITPro, CloudPro, and ChannelPro staff writer, covering topics like security, privacy, worker rights, and startups, primarily in the Asia Pacific and the US regions. Zach joined ITPro in 2017 where he was introduced to the world of B2B technology as a junior staff writer, before he returned to Argentina in 2018, working in communications and as a copywriter. In 2021, he made his way back to ITPro as a staff writer during the pandemic, before joining the world of freelance in 2022.

-

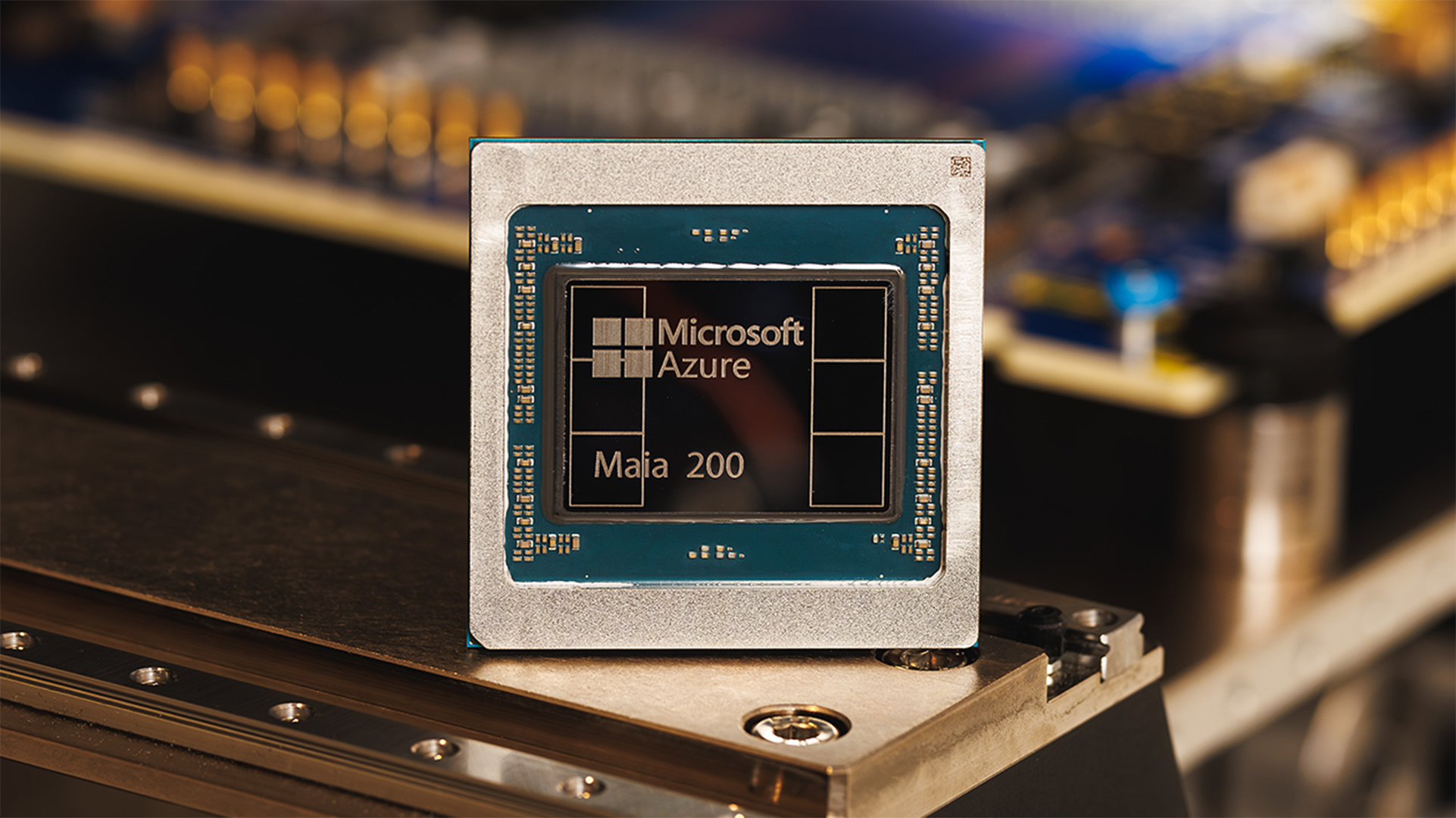

Microsoft unveils Maia 200 accelerator, claiming better performance per dollar than Amazon and Google

Microsoft unveils Maia 200 accelerator, claiming better performance per dollar than Amazon and GoogleNews The launch of Microsoft’s second-generation silicon solidifies its mission to scale AI workloads and directly control more of its infrastructure

-

Infosys expands Swiss footprint with new Zurich office

Infosys expands Swiss footprint with new Zurich officeNews The firm has relocated its Swiss headquarters to support partners delivering AI-led digital transformation

-

IBM unveils its 'most powerful' 433-qubit quantum processor

IBM unveils its 'most powerful' 433-qubit quantum processorNews The Osprey is three times more powerful than IBM's 127-qubit Eagle processor the company launched a year ago

-

Blackberry revenue falls by 4% as cyber security division takes hit

Blackberry revenue falls by 4% as cyber security division takes hitNews Despite this, the company’s Internet of Things (IoT) division increased its revenue by 28% as it attracted new customers from the automotive sector

-

US lawmakers warn Apple against using Chinese chips in next iPhone

US lawmakers warn Apple against using Chinese chips in next iPhoneNews Senators ask the US director of national intelligence to investigate a Chinese chipmaker’s military ties

-

New Huawei Mate 50 phone can link up with Chinese satellite system

New Huawei Mate 50 phone can link up with Chinese satellite systemNews This makes it the first smartphone maker to bring satellite communication technology to the consumer market

-

SK Hynix splashes out $11 billion on new semiconductor plant

SK Hynix splashes out $11 billion on new semiconductor plantNews The company will produce memory chips, but will reportedly decided closer to the time whether they will be DRAM or NAND flash chips depending on market conditions

-

Intel strikes $30 billion private equity partnership to fund Arizona plant expansion

Intel strikes $30 billion private equity partnership to fund Arizona plant expansionNews Brookfield Infrastructure Partners will invest around $15 billion into the expansion of the chipmaker’s Ocotillo campus

-

The best 3D printer tools and accessories for your business

The best 3D printer tools and accessories for your businessIn-depth Every business using 3D printers should be aware of these essential extras to raise its output to the next level

-

LED vs laser printers: What should your business choose?

LED vs laser printers: What should your business choose?In-depth Laser and LED printer technology is similar, but each come with their own unique benefits that could make them best for your company