What is smart manufacturing and is it the future?

As the industrial and digital worlds collide, what is smart manufacturing and what are its elements and benefits?

Smart manufacturing is an emerging field surrounded by hype and, like all buzzwords, its definition can shift as new tools become more widespread and new terms find their way into the conversation.

In a broad sense, smart manufacturing is enabled by the design of processes using digital technology, which makes operations adaptive and flexible and responds to changes faster – sometimes entirely automatically.

Frameworks like the Internet of Things (IoT), Industrial Internet of Things (IIoT), big data analytics, factory robots, and AI are the spokes of a wheel which work both independently and interdependently to drive smart manufacturing.

A 2011 working group convened by a Bosch executive and the president of the German National Academy of Science and Engineering defined it as:

“Manufacturing that improves its performance aspects with integrated and intelligent use of processes and resources in cyber, physical, and human spheres to create and deliver products and services, which also collaborates with other domains within enterprises' value chains.”

What is smart manufacturing: the common elements

Smart manufacturing builds are as varied as the companies and plants that use them, but common elements can include:

- IIoT sensors: A sensor tracks information in real-time such as how many pieces go overhead on a conveyor belt. Together with set parameters such as how long the belt is supposed to last, it can produce a more accurate maintenance schedule. It can then be replaced during downhours without interrupting operations before it becomes a problem – no more replacing still-working components because of a static maintenance plan or the expensive delays of a mid-production failure. Setups such as this often run on a private 5G network in order to operate with the lowest possible latency.

- Cobots: A command is sent to an autonomous robot fleet, and the human operator doesn't need to control (or know) which bot gets the job. The system figures out the unit that's closest and most suited, automatically engaging safety behaviors like stopping when there's a human coworker in its path.

- Digital twins: If you're inputting a new line into a plant, you can create a digitised 3D model of the whole operation, connect it with local Geographic Information System (GIS) data, and your live model can report on where best to situate components based on proximity to power outlets, input channels like doors, etc. At the largest scale, this process has been applied to entire nations such as Singapore’s digital twin.

Smart manufacturing vs industry 4.0

Although terms like smart manufacturing and industry 4.0 – sometimes referred to as the fourth industrial revolution (4IR) – are often used interchangeably, they refer to quite different things.

Sign up today and you will receive a free copy of our Future Focus 2025 report - the leading guidance on AI, cybersecurity and other IT challenges as per 700+ senior executives

Like industry 4.0, smart manufacturing also connects up and downstream as data from raw material inputs and aftermarket consumer use metrics are fed back into the equation to constantly improve performance.

But it refers more directly to resources in the digital world helping processes in the physical world interact with each other better and creating the maximum possible value from physical infrastructure.

If you remember nothing else about the difference, remember this; industry 4.0 is the philosophy and smart manufacturing is the toolset.

RELATED RESOURCE

As manufacturing became increasingly computerized in the 21st century, former World Economic Forum founder Klaus Schwab coined the term 'fourth industrial revolution' to refer to the new manufacturing era following the steam age (18th century), electrical age (early 20th century) and early automation age (the 1970s).

It describes methodologies that connect systems and domains together, blurring the lines between physical and digital as well as producer, supplier, and consumer. Industry 4.0 is partly about technology but also human capital, enabling constant upskilling and reskilling.

What technologies are associated with smart manufacturing?

Some of the technologies most commonly used in smart manufacturing include:

- Machine learning (ML)

- Augmented reality (AR) and virtual reality (VR)

- Robotics

- Additive manufacturing

- Big data

Each technology plays its own role in bringing together all the boosts to efficiency and oversight that can be unlocked through smart manufacturing.

ML & AI

Algorithms collect, synthesize and action data that comes out of connected manufacturing systems across the supply chain. Information can be processed via AI or ML to predict product yields or identify inefficiencies on the manufacturing floor.

AR & VR

Whether it's a whole digital twin or simple a visual overlay of a single data point on a real-world system, using AR and VR you can walk through, look around and explore data presented in a digitized world to test a change you intend to make before committing funds and time to the real thing. Mixed reality is transforming city and urban planning already and has strong potential in manufacturing environments.

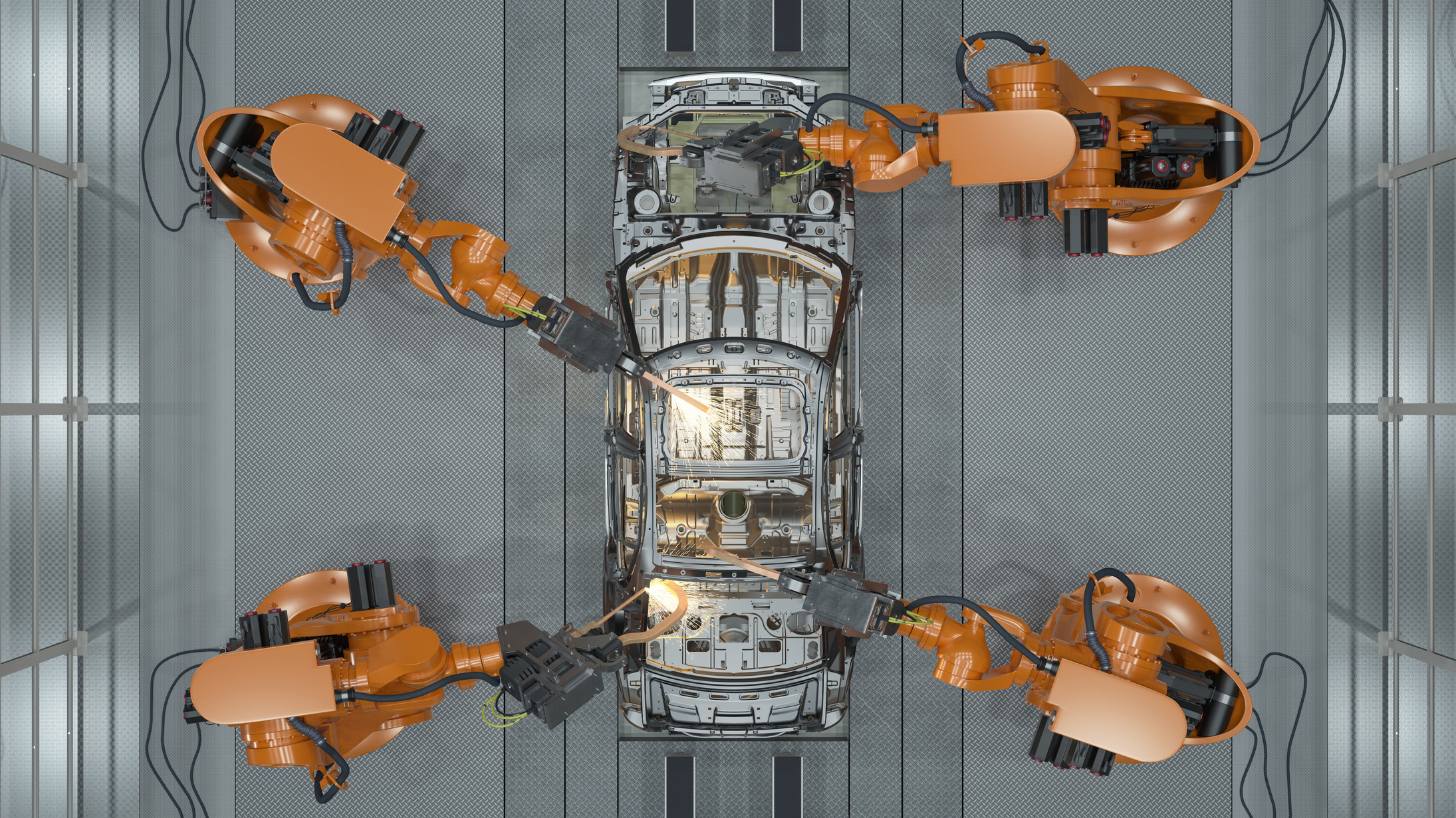

Robotics

A capstone technology since the 1960s, today robots come in more shapes and sizes than ever, can be programmed to perform – or learn – a wider variety of actions and can work safely alongside human colleagues.

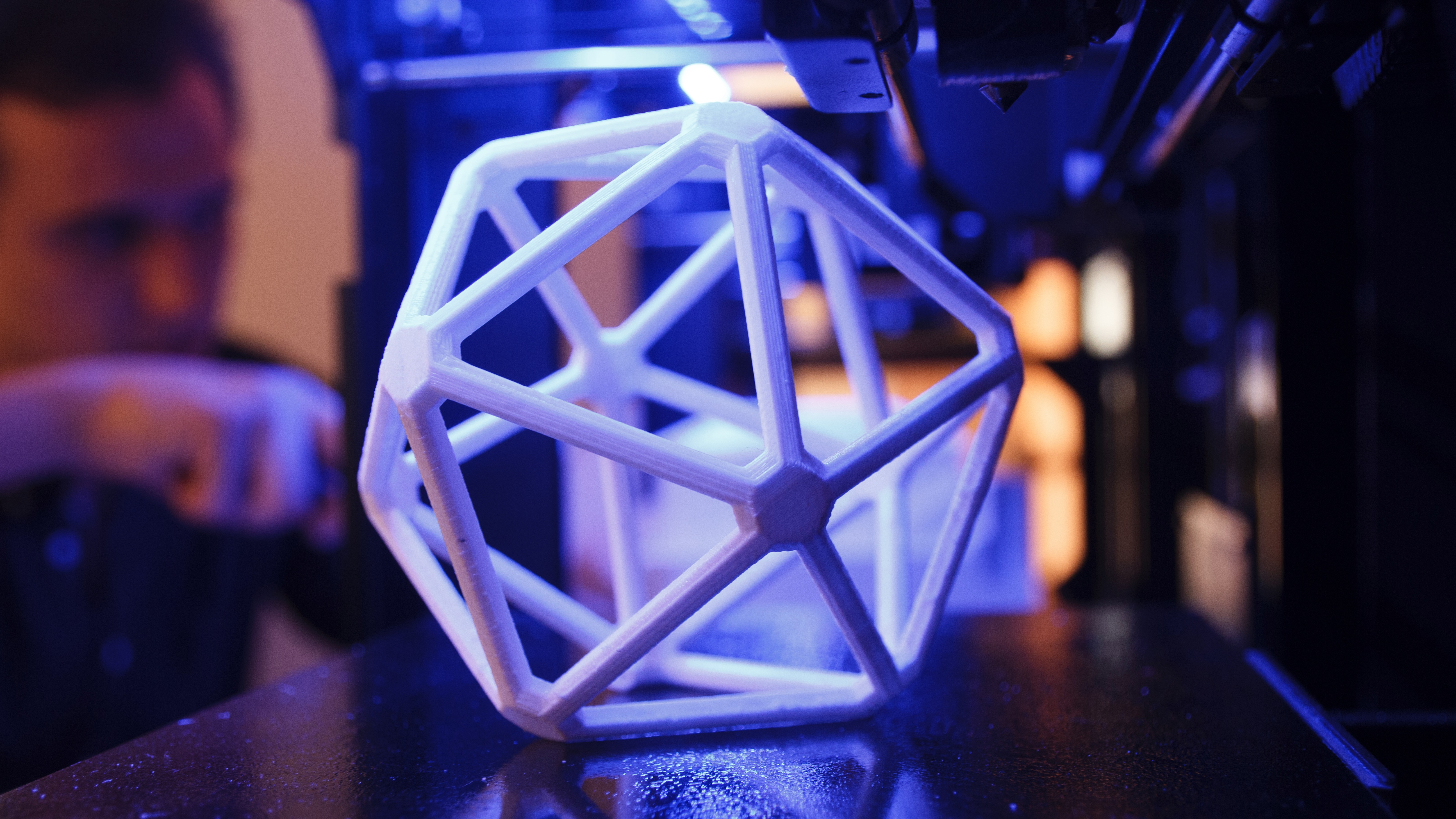

Additive manufacturing

Also known as 3D printing, additive manufacturing involves building an item out of many small layers of material and has been part of manufacturing longer than most people realise. The latest generation of ever-finer prototyping and hybrid products/processes gives you more flexibility and higher speed to market than ever.

Big data

When every sensor on the factory floor is connected to the product throughout (and sometimes beyond) its manufacturing lifecycle, big data captured via IIoT sensors can provide constant insight into how to improve. Some of this data can be processed using edge computing for instant decision-making, while much of it can be stored for predictive analysis.Smart ports are a prime example of environments in which this has been successfully trialled.

Is smart manufacturing right for your business?

There are a lot of providers hoping you'll buy their smart manufacturing systems, so naturally lots of hype has been built artound the technology. The upsides are indeed considerable: smart manufacturing can improve production whether your aim is to reduce cost, work faster or create more room to innovate. It can also mean fewer nasty surprises from maintenance issues or breakdowns, along with slashed energy bills and reduced waste through efficiency gains.

You'll have fewer fail points and reruns, and everyone from your CFO to your customers will benefit. But do your research (and sums). Smart manufacturing can have a high implementation cost, so weigh up how much it will actually add to your bottom line (and over how long). It's also very complex, which means if you cut corners to establish it in systems or staff, it might cost more than it saves.

Adopting smart manufacturing will also put extra demands on security teams. For example, the number of IoT sensors required for an effective smart manufacturing setup call for a strong IoT security strategy.With systems all connected to each other (as well as those of suppliers, sales and marketing teams, customers, regulators and potentially countless others) across networks which could face the public internet, effective cyber security might mean the difference between business as usual and a costly data breach or ransomware attack.

Whatever the risks and rewards, smart manufacturing is a core part of the future, all the more reason to spend time now figuring out if it's right for your business.

Drew Turney is a freelance journalist who has been working in the industry for more than 25 years. He has written on a range of topics including technology, film, science, and publishing.

At ITPro, Drew has written on the topics of smart manufacturing, cyber security certifications, computing degrees, data analytics, and mixed reality technologies.

Since 1995, Drew has written for publications including MacWorld, PCMag, io9, Variety, Empire, GQ, and the Daily Telegraph. In all, he has contributed to more than 150 titles. He is an experienced interviewer, features writer, and media reviewer with a strong background in scientific knowledge.

-

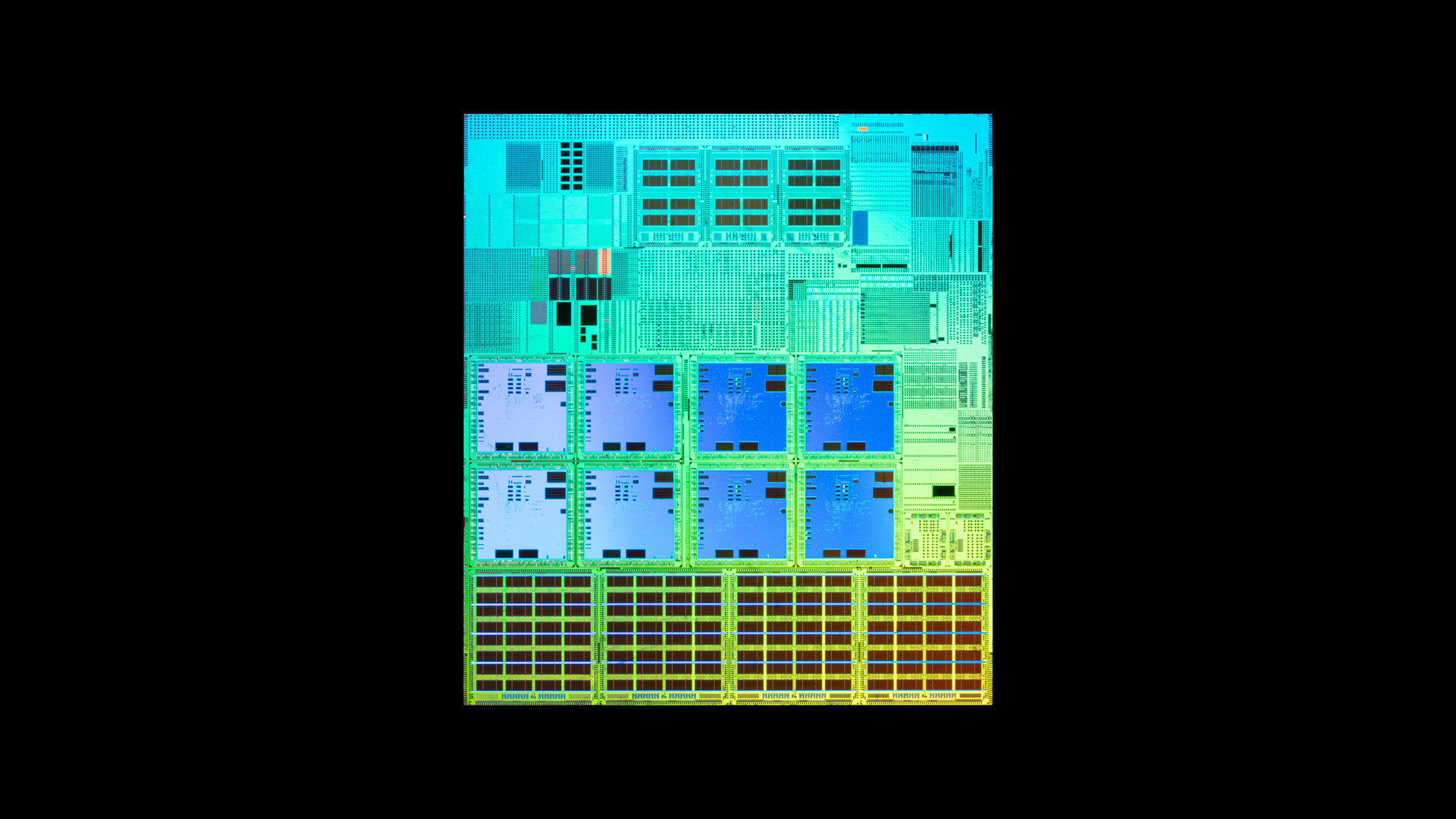

What is Microsoft Maia?

What is Microsoft Maia?Explainer Microsoft's in-house chip is planned to a core aspect of Microsoft Copilot and future Azure AI offerings

-

If Satya Nadella wants us to take AI seriously, let’s forget about mass adoption and start with a return on investment for those already using it

If Satya Nadella wants us to take AI seriously, let’s forget about mass adoption and start with a return on investment for those already using itOpinion If Satya Nadella wants us to take AI seriously, let's start with ROI for businesses